Solutions for Industries ▼

TEXTILE ➜

❉ ┃ PHARMACEUTICALS

❉ ┃ POWER PLANTS

❉ ┃ PAPER & PROCESS

❉ ┃ DOMESTIC & HOSPITALITY

Water is used extensively in almost all stages of textile industry. Each stage like pretreatment, dyeing, bleaching, printing, washing needs huge volume of water. The process water needs to be either free or contain regulated quantities of impurities, viz. Colour, Turbidity, pH, Total Dissolved Solids (TDS), Total Suspended Solids (TSS), Temporary & Permanent Hardness. A good supply of pure water is very important for bleaching and/or dyeing because a number of faults could be attributed to the use of unsuitable water in processing of textiles. With the decreasing availability of good water and ecological concerns over polluted water, as set of tools been devised by our engineers to arrange quality process water and recycling of used water in textile plants.

Treated water is needed at the very first stage where bleacing, dyeing & washing of fibres and fabrics take place. In the process, when hot water is required, specially treated De-mineralised water is used in order to prevent scaling in boilers. The effluent coming out as a result of washing, needs treatment before discharging into nature. A good percentage of the wastewater are been recycled for further use.

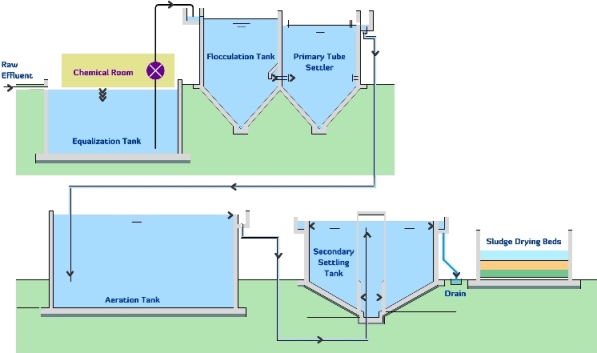

Wastewater handling

The wastewater coming out after washing and dyeing of fibres and fabrics need treatment before being discharged into nature. To reduce wastage a good amount of waste is been recycled for further use.

The generated effluent is typically full of detergents and dye residues, which needs neutralization prior to biological treatment.Plants supplied by Signea does not contain movable parts inside keeps the maintenance cost at low. Apart from standard pumps and blowers, no other rotating machines are included.

The static clarifiers supplied operate on Sludge Blanket Principle for optimum efficiency. The treated effluent shall always comply with applicable Pollution norms of the countries.

The treated wastewater is further processed by Filtration, Ultrafiltration and RO to make it suitable for re-use.

The accumulated Sludge is made into briquette form by Press or Centrifuge for disposal.

ZERO DISCHARGE TREATMENT SYSTEMS are also provided upon specific customer request.