Components ▼

❉ ┃ CLARIFIERS ❉ ┃ FILTERS & VESSELS ❉ ┃ MEMBRANES

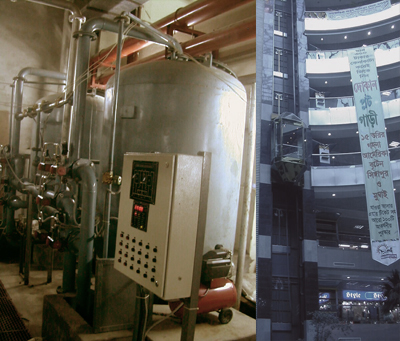

De-Ionisers

Ion Exchange Method for Purification of Water

Ion Exchange method is deployed to remove soluble impurities from water. The two major de-ionization applications are Softening and De-Mineralization.

The presence of Calcium, Magnesium salts (Cl-, SO4=, HCO3-, NO3- etc.) cause hardness in water. The process of removal of such salts using a stronger Cation (Na+) is known as Softening.

The other application, where the ions of dissolved salts get replaced by H+ and OH- ions to form pure water is known as De-Mineralization (DM). The process is initiated by application of chemicals, viz. Acid (for H+ cation) and Alkali (for OH- anion).

Softeners

Removal of Ca & Mg salts (HCO3, Cl, SO4, NO3) which cause HARDNESS in water. Done by replacing Ca and Mg with Na by a Strong Cation Resin in Na+ form.

To prevent scale formation in pipelines, boiler tubes & shell, other heat exchangers, cooling towers etc.

HVAC, BF Water, Process water (for bleaching, dying, other chemical processes), Cooling tower make-up etc.

Done by cation exchange resin in Na+ form.

During service cycle the Na+ replaces Ca++, Mg++, Mn++ etc. the hardness causing cations. This process yields sodium salts as a end product of softening, hence TDS (Total Dissolved Solids) does not come down. Regeneration is done by passing brine solution through resin to recharge the sodium.

De-mineralisation (DM)

A treatment process that reduces the total salt content of water.

By conventional method - Ion Exchange ResinsBy Membrane Separation - Reverse Osmosis Plants

With the help of cation (in H+ form) & anion (in OH- form) exchange resins.

Firstly the H+ replaces the cation part of the salts present. Next the OH- replaces the anion part of the ACIDS. Thus HOH i.e. water is formed. Hence in this process the TDS comes down to desired levels. After their respective cycles the cation & anion exchange resins are regenerated by using acid & alkali respectively.

Often used as a downstream process to Reverse Osmosis for additional polishing of water with lesser cost.

Applicable to

Textile, Food & Beverages, Pharmaceuticals, Power Plants, Electronics, Automobile, Process Industry etc..